The most important benefits of using the Gantry Slipform method compared to a standard slipform solution for caisson production.

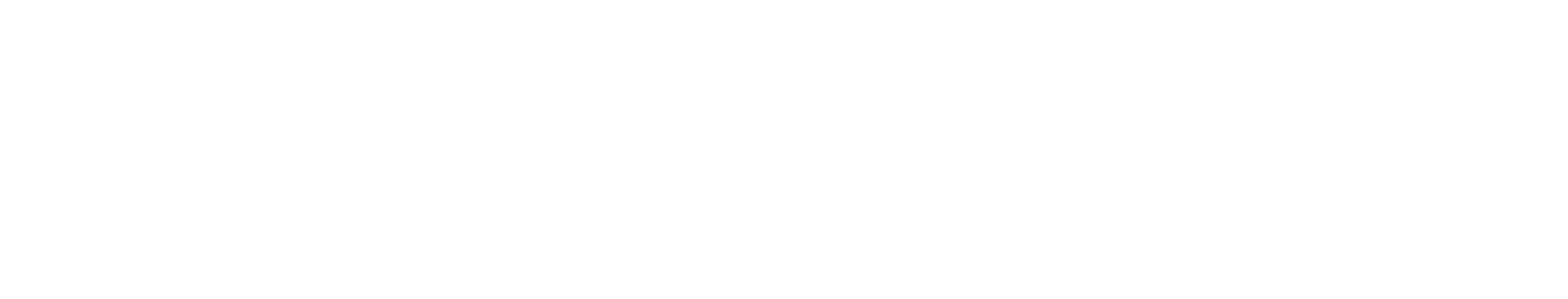

Cost comparison

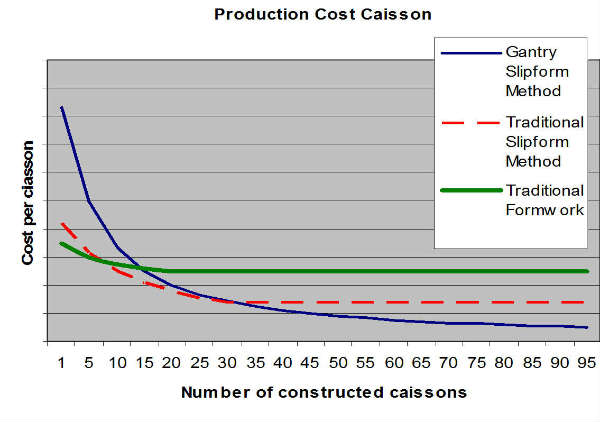

Standard, or Traditional Slipform, requires a complete slipform assembly and dismantling for each caisson. The Gantry Slipform method on the other hand never has to be dismantled and reassembled during the complete production phase. Bygging-Uddemann used Standard Slipform for all caisson projects during the 60’s and 70’s before we developed the Gantry Slipform method. With the experience from using both types of slipform methods we have learned that the slipform cost for the Gantry Slipform method is the most economical solution on projects with more than approximately 30-35 caissons. See the diagram.

Jack tubes and yokes / differences

Traditional slipform requires continuous installation of jack tubes for the slipform jack to climb on. This operation disturbs the installation of rebar. With the Gantry Slipform method the slipform climbs on solid steel rods completely outside the caisson geometry and never interferes with the rebar installation. The jack rods will also last for the complete project.

Working conditions / material storing facilities

The Gantry Slipform method provides a very spacious working place since it provides two large work decks to operate from (Slipform Deck and Upper deck). The extra working space provides a much safer and effective working area since rebar material can be stocked in advance for distribution before the slipform starts.

Winches instead of construction cranes

There is no need for construction cranes with the Gantry Slipform method since all material is handled by winches supported by the gantry roof structure. The winches can haul material from the concrete lorries at the pick-up area directly into the caisson walls.

Keeping the same caisson geometry throughout the project

To be successful with a standard slipform set-up with many dismantling and reassembly operations its always very important to perform the set-up at assembly exactly the same throughout the project. With all the wear and tear involved with repeated re-assembly it can be difficult after a while to maintain the exact shape of the slipform shutters. The wall thickness can also vary, mostly it widens, which will cause higher concrete consumption.

Safety aspects to consider

Repeated dismantling and assembling always increases the risk for labour accidents with standard slipform. Safety precautions such as safety nets, hand railing, etc., are often neglected in a standard slipform after a couple of re-assemblies. Weather protection is very poor in standard slipform while the Gantry Slipform offers a permanent rain and wind protection which allows uninterrupted work during bad weather.