Our steel tank erection set-up consist of following parts:

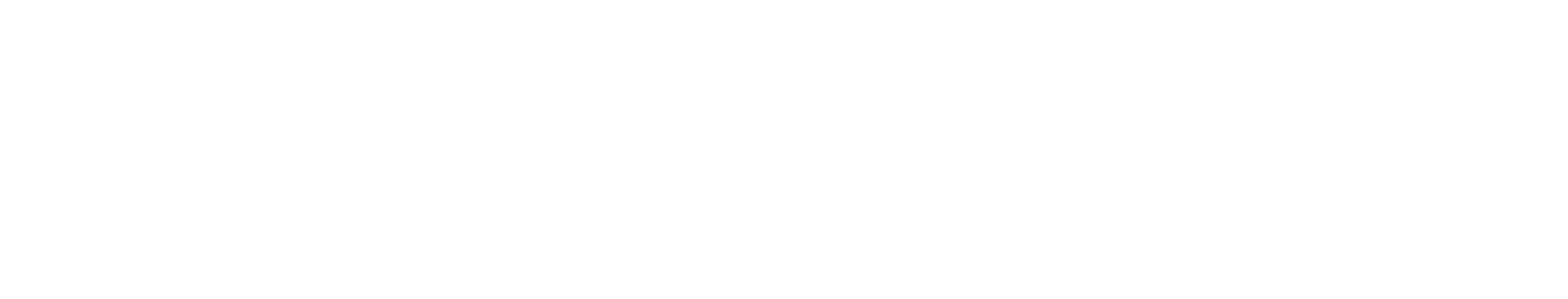

- Lifting trestles

- Guide trestles

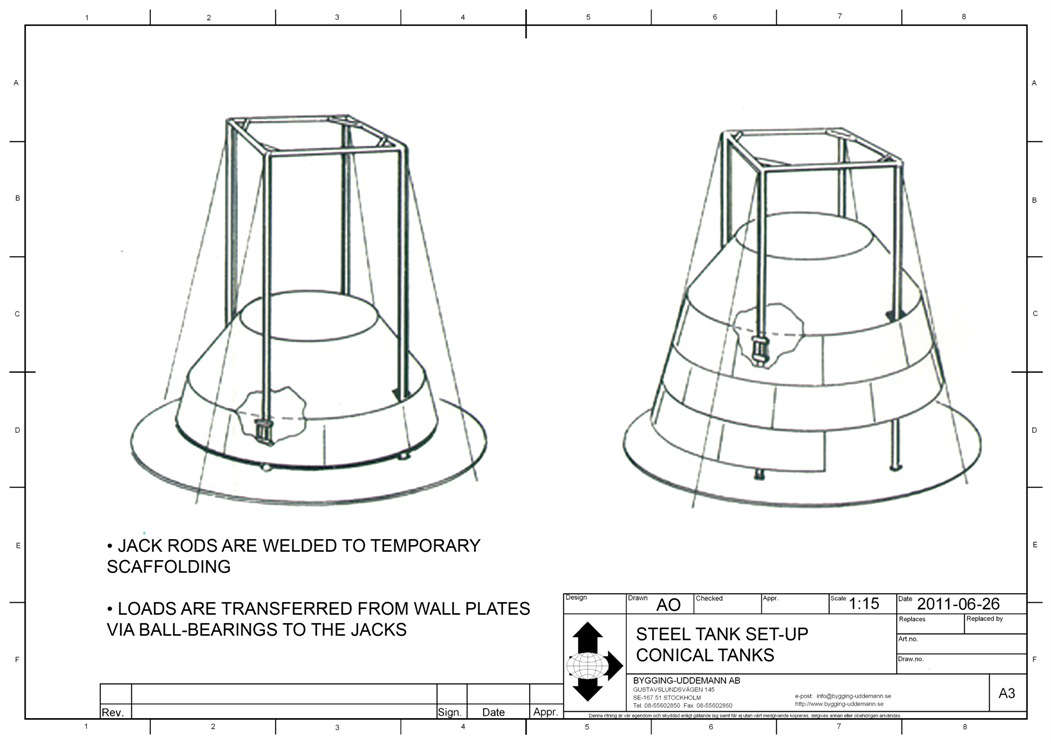

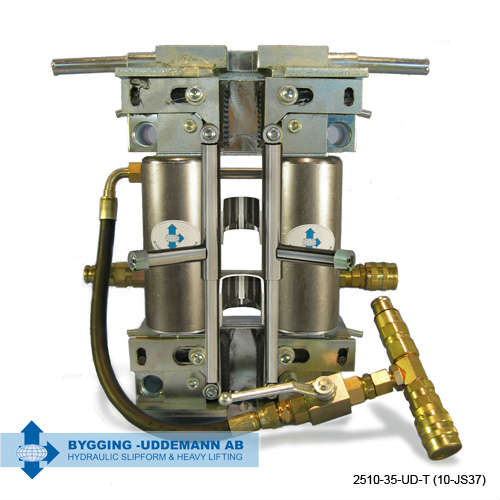

- Hydraulic climbers

- Hydraulic power pack

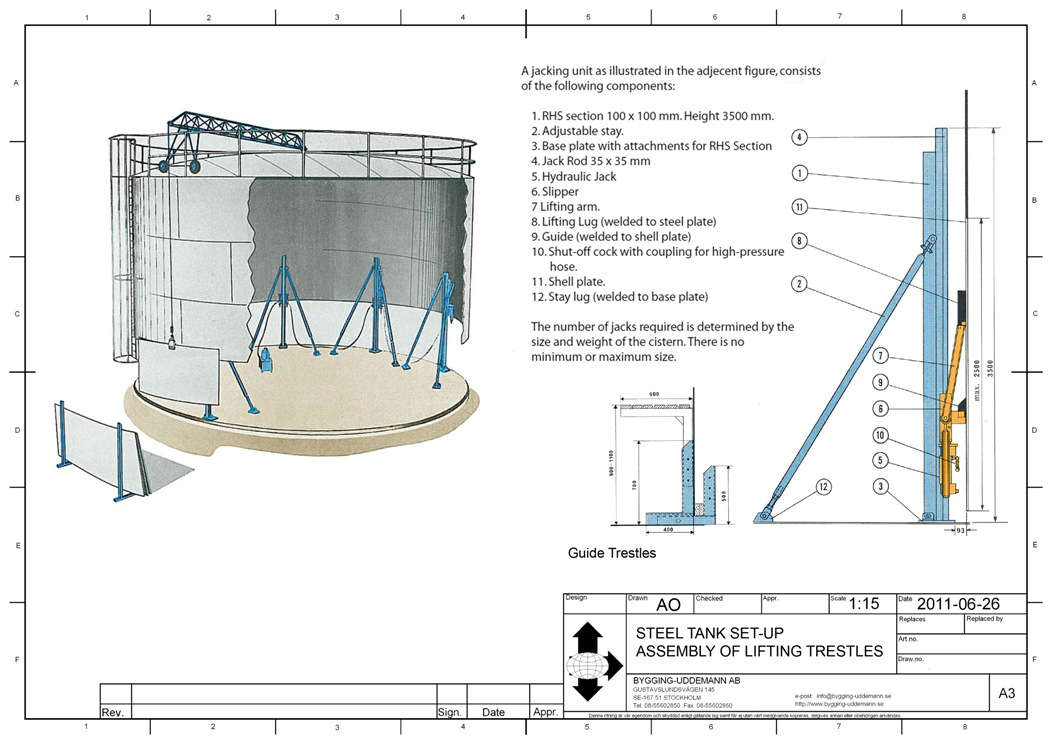

The method is based upon the principle that – after the tank bottom is first laid out – construction starts with the tank roof and the top shell assembly, all at foundation level. This completed upper part of the tank is then lifted by tank jacks mounted on lifting trestles, positioned inside and along the circular wall.

When the upper part is lifted to the height of one tier of plates a new tier is welded underneath the first one. This procedure is repeated until the tank has reached its full height.