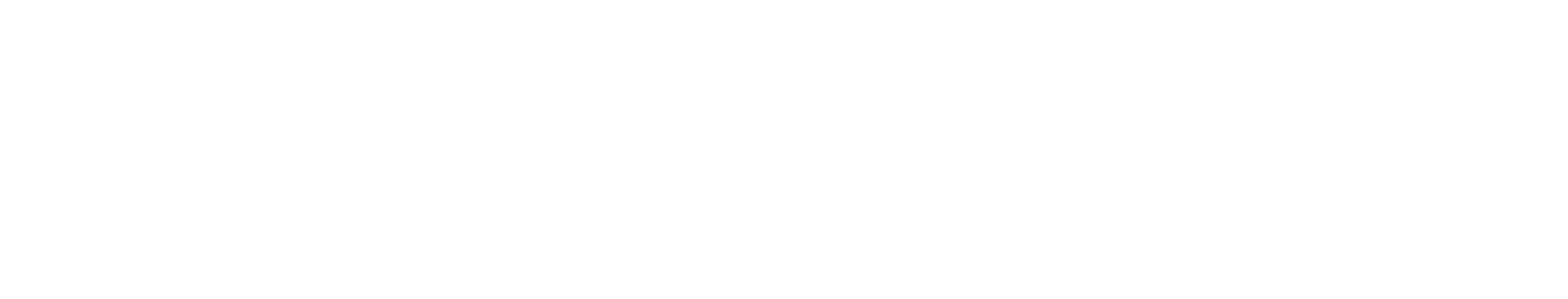

Installation of a gravity-based foundation

A challenge during construction and installation is the size of the facility, and that it must be designed to withstand large forces of nature. Material quality is therefore of the utmost importance.

The concrete bottom of the structure is built in a dry dock. Most requirements need to be placed on the dry dock to ensure its suitability. Examples of requirements are sufficient depth, taking into account the size of the base, the design of the base, the bearing capacity of the dock, its drainage system and its bottom material if the gravity-based foundation is placed directly on the bottom. The dry dock must also be waterproof, but have an openable exit so that the foundation can be towed out. It must therefore withstand enormous forces from all over the sea.

It is then transported out to a protected deep port, where it is moored. Thereafter, the towers are created by slipform casting in a continuous process.

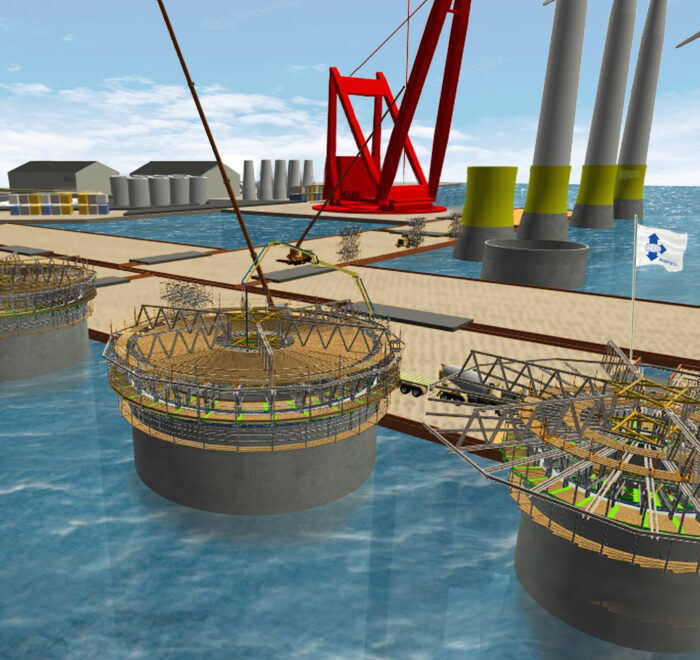

The weights are then removed and the whole structure is towed out to the installation site using tug boats. Once there, ballast is placed to secure the foundation to the seabed.

Offshore wind power with gravity-based structure

Structures based on gravity for offshore wind turbines have been shown to have several advantages compared to the alternatives. In cases where the seabed is not sufficiently stable, however, other methods are preferred, such as different types of piling.

Two factors that speak for gravity-based structures over the alternatives are the environmental impact and the economic aspect. Since no piles need to be installed, the impact on the seabed is reduced, as is the noise level during installation. Mounting steel piles causes higher noise levels that can disturb the sea fauna. Concrete that is often used for the base is also a relatively cheap material. It can be used in deep water without any problems. Steel piles require larger diameters with increased water depth, which further contributes to the cost.

When building wind turbines of this structure, however, there are some challenges to take into account. Above all, it is important to be able to produce a construction that resists cyclic forces, ie forces that vary over time, which naturally gives more wear than static forces. These forces come from natural variations in wind speed and wave energy.

Offshore wind turbines with gravity-based construction are currently located in Sweden, Finland, Norway, Belgium and Germany in Europe and interest is growing in several parts of the world.

Maintenance of offshore wind power

Most offshore wind power plants built with gravity-based foundations are made of concrete. This has the great advantage that they require very little maintenance compared to, for example, metal constructions. Steel structures also have a shorter service life and need to be replaced more often. Concrete is a material that has less impact on the environment – when concrete structures need to be replaced after 20-50 years, the old ones can easily be recycled.

In summary, gravity-based constructions have several advantages over traditional piling methods: less environmental impact on the seabed, less noise that disturbs underwater life during installation, materials that require very little maintenance and withstand the test of time, lower material costs, flexibility in size – everything from huge oil platforms to wind turbines can be built according to this method – as well as the possibility to install in varying temperature conditions and climates. Wind power companies with offshore wind power thus have much to gain from switching to gravity-based technology in cases where it is possible.